Remediation of soil and sediment contaminated by Heavy Metals

Remediation of soil and sediment contaminated by Heavy Metals

Industrial activities originated significant contaminations from inorganic substances, which interact with the sediment and soil matrix in different ways. DIEMME SOIL WASHING in the construction of the reclamation plant applies a wide range of process technologies that use chemical-physical mechanisms that allow to concentrate the contaminants progressively in a progressively reduced volume. A high recovery of raw materials such as inert materials, gravel, sand, etc. is obtained. can also be reused directly on site.

The possible integration of the soil washing process with solidification / stabilization post-treatments allows to reduce the dangerousness of the agglomerate produced, allowing its disposal in less expensive landfills. The economic advantages are considerable, among which are mainly reported:

- Recovery of a high percentage of raw materials

- Less use of chemical reagents and always optimal use of them

- Ability to carry out remediation directly on the contaminated site and consequent elimination of the economic burden for the transport and disposal of the contaminated matrix

- Volumetric reduction and concentration of contaminants

- Possibility to solidify / stabilize the residual contaminant, further reducing its disposal costs

Also for these contaminants, the study of site specific analytical and documentary data allows an evaluation of the possible applicability of the process as well as of any functional variables. In the subsequent laboratory tests that can be carried out at DIEMME SOIL WASHING carried out on a small sample of material, the main dimensional parameters and operating results obtainable are verified in order to eventually carry out experimental tests with an industrial pilot plant.

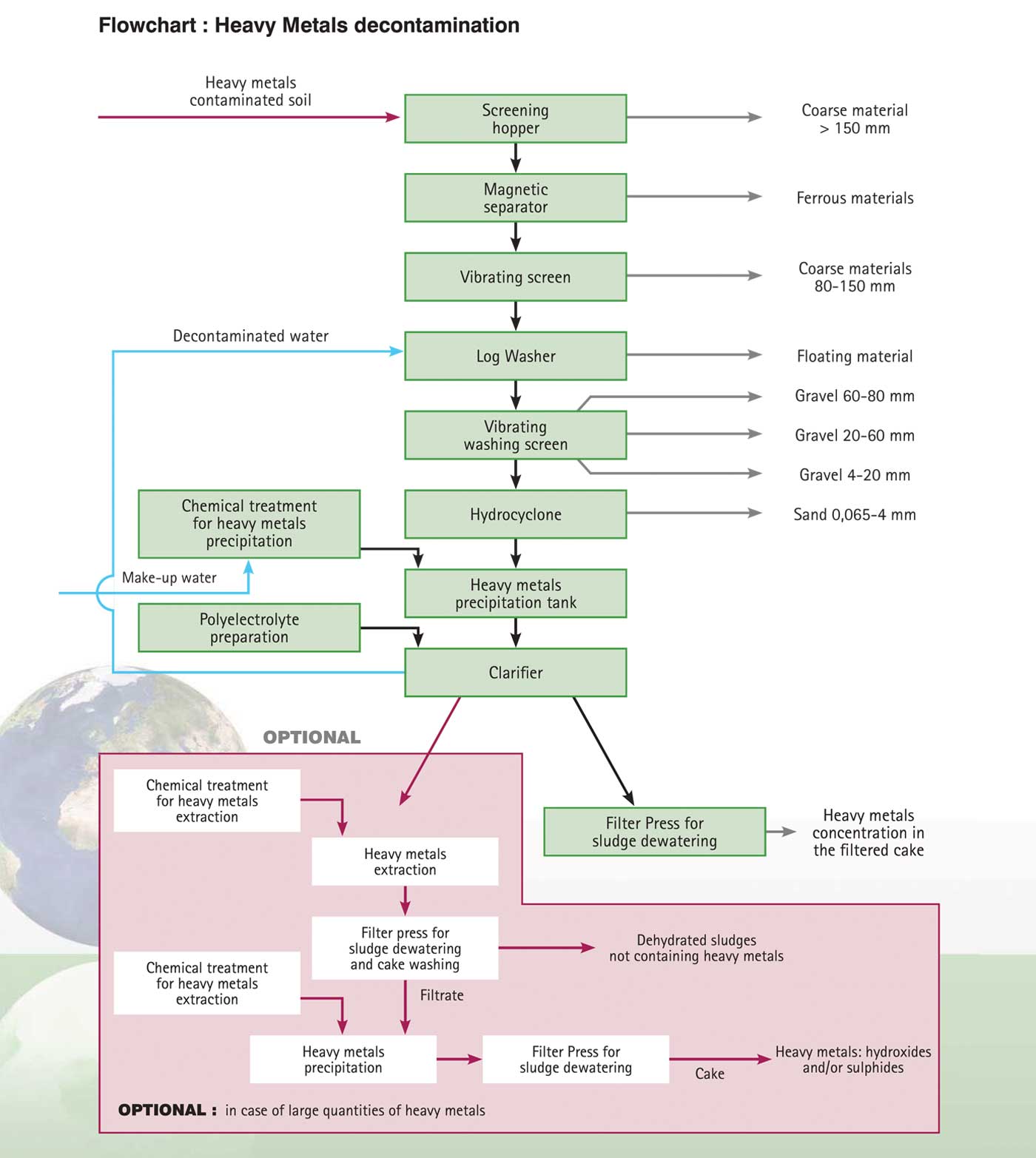

The flow chart illustrates the specific phases that make up a typical DIEMME SOIL WASHING plant for the remediation treatment of matrices contaminated by heavy metals.