What is a filter press?

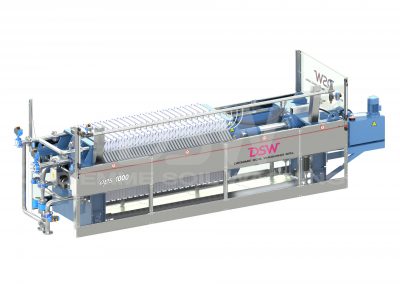

Everyday industrial processes produce millions of cubic meters of sludge that has to be dewatered and filter press is the best industrial machine for this function. A filter press is consists of: frame, plate pack which forms the filtration chambers, filter cloths, filtrate collectors, feed pump and hydraulic system. This last aligns and closes under pressure the plate pack, later the feed pump extracts the sludge and pumps it, through the feed collector, inside the chambers where the filtration takes place. Filtration process withholds solid particles inside the chambers while the liquid phase migrates through is dischargerd from the filtrate collector. Some application sectors of filter press are listed below:

- Chemical industry

- Mining industry

- Food industry

- Ceramic industry

- Metallurgical industry

- Textile industry

- Municipal depuration

The Filter Presses designed and manufactured by DIEMME SOIL WASHING differ in the degree of automation that can be obtained, from manual to semi-automatic up to fully automatic.

Historical notes about filter press

The necessity of an industrial machine able to separate solid and liquid phases of a sludge was born in England during the Second Industrial Revolution, historic time in which productive processes on large scale started. Plates on first filter press were made of wood and used for sugar purification. Later, after the introduction of stell for industrial use, plates became in metal and finally, after the Second World War and the introduction of plastic, polymeric like in new generation filter presses.

For more informations

Operation of filter press

Operation of a new generation filter press is simple and it can be summarized in the phases listed below:

- Feeding: suspension is pumped inside the plates pack at low pressure through the feed collector.

- Filtration: feed pressure is increased up to different values depending on the sludge type and it can get to 16 bar. In that way, solid phase is withheld and compressed inside chambers meanwhile liquid phase is evacuated from discharge collectors. In this step, filter clothes which cover chambers are very important; these are several and are chosen in function of the chemical and granulometric properties of the product to treat.

- Depressurisation: at the end of the filtration phase, pressure inside filter press components is reduced until atmospheric one.

- Discharge: the plates pack is opened thanks to a plate shifting system allowing to discharge solid panels formed during filtration.

- Washing: filter clothes are washed with high pressure water (50 bar / 725 psi) to recover the filtration capacity.

- Closing: the plates pack is closed under pressure to restart a new cycle.

Modern filter presses can also install, in addition to standard recessed plates, membrane plates which allow to apply the squeezing of panels after the filtration phase in order to further reduce residual moisture. Another possible solution is the application of the blowing phase, through the set up of a blowing system to reduce residual moisture in panels after the filtration phase. Squeezing and blowing steps can also be combined according to the requested performance.

Operation of filter press

Operation of a new generation filter press is simple and it can be summarized in the phases listed below:

- Feeding: suspension is pumped inside the plates pack at low pressure through the feed collector.

- Filtration: feed pressure is increased up to different values depending on the sludge type and it can get to 16 bar. In that way, solid phase is withheld and compressed inside chambers meanwhile liquid phase is evacuated from discharge collectors. In this step, filter clothes which cover chambers are very important; these are several and are chosen in function of the chemical and granulometric properties of the product to treat.

- Depressurisation: at the end of the filtration phase, pressure inside filter press components is reduced until atmospheric one.

- Discharge: the plates pack is opened thanks to a plate shifting system allowing to discharge solid panels formed during filtration.

- Washing: filter clothes are washed with high pressure water (50 bar / 725 psi) to recover the filtration capacity.

- Closing: the plates pack is closed under pressure to restart a new cycle.

Modern filter presses can also install, in addition to standard recessed plates, membrane plates which allow to apply the squeezing of panels after the filtration phase in order to further reduce residual moisture. Another possible solution is the application of the blowing phase, through the set up of a blowing system to reduce residual moisture in panels after the filtration phase. Squeezing and blowing steps can also be combined according to the requested performance.